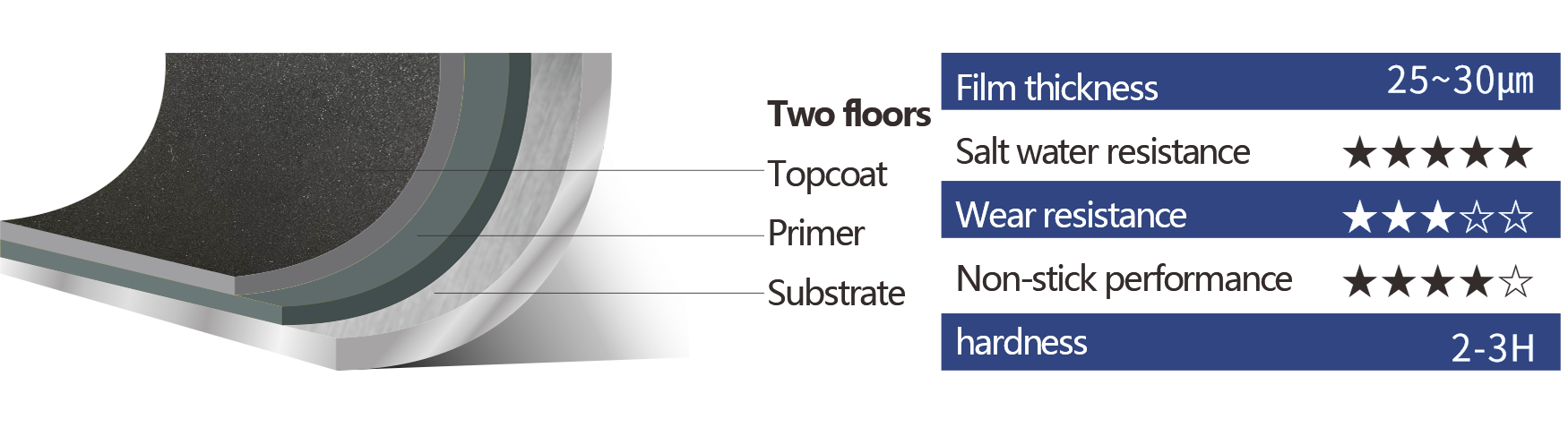

The two-layer coating is a basic grade fluororesin non-stick coating developed by Dae Young Chemical.

The product has good cost-performance ratio, strong practicability, good non-stickiness and glossiness.

Darong cooperates with a well-known international testing institution(SGS), to ensure that products and services comply with global standards and local regulations, and we can tell you or your end clients. It is proved that the Mega two-layer coatings are in line with domestic and international standards and specifications.

| Test Item | Test method | Test rusult |

| Pencil hardness | Check if coating film will cause crack with 1KG pressure horizontal stroke at 45 ° inclination by MITSU_BISHI brand HB~9H pencil. | 2~3H(According to ASTM-7875 testing methods) |

| gloss | Test 4~6 sites of coating surface at the bottom of the pan by gloss tester, take the average value. | 10~20 |

| Wear resistance | Keep 3M brand sponge on the coating film, pour into water that can cover the pan bottom, pour dishwashing liquid detergent with 2KG(0.115KG/㎡)pressure friction back and forth( Back and forth spacing about 10CM), recording back and forth cycles until the film has been worn out only 10% film remain. | Over 3000 cycles |

| Adhesion | Use knife to cut 100 quantity spacing 2mm squares, completely stick adhesive tape and tear, repeat 10 times. | 100/100 |

| Non-stick | Pour egg white on the coating film, heating to 160~180℃, after fully cooked, check if it can be peeled off from the coating film. | over 10 cycles |

| Saltwater resistance | Pour 10﹪ salt,water into the pan, heating at 70 ℃ ~90 ℃ andmaintaining, observe if causes corrosion. | More than 48 hours |

浙公网安备33020602000690号