Excellent abrasion resistance and salt water resistance.

It can prompt suitable temperature by the way the pattern appears when cooking.

Good thermal conductivity,Can heat up quickly in a short time by adding Graphene inside, Graphene also makes the coating performance more stable and has sterilizing effect.

For health and environmental protection, PFOA-free, heavy metals free.

Darong cooperates with a well-known international testing institution(SGS), to ensure that products and services comply with global standards and local regulations, and we can tell you or your end clients. It is proved that the Grafino Coating coatings are in line with domestic and international standards and specifications.

| Test content | Test method | Test results |

| Pencil test | The pen core is flattened, and the line is drawn by the gravity of 1KG at an angle of 45°. | Above 3H |

| Abrasion resistance | Use 3M scouring pad 1.5KG to test wear resistance. | 46,000 times (Japanese GIS standard 100,000 tests passed) |

| Adhesion test | Cross-cut on the coating surface at a pitch of 1 mm, press and adhere with 3M tape, and peel off repeatedly more than 10 times. | Normal |

| Water resistance | Boil for 8 hours and let it cool down naturally. | Normal |

| Oil resistance | Put the soybean oil at 200℃ for 8 hours and take it out to see if it changes. | Normal |

| Salt water resistance | After setting the internal temperature of the salt sprayer to 40±2℃, spray a solution containing 10% sodium chloride. | 120 hours (72 hours as the standard) |

| Not sticky | After the surface temperature reaches 80°C, perform a non-fried egg test. After the surface .temperature reaches 160~170°C, check whether the eggs can be easily separated from the frying pan. | |

| Stain resistance | Boiled milk | No discoloration (3 times) |

| Barbecue | No discoloration (3 times) | |

| Fried fish | No discoloration (3 times) |

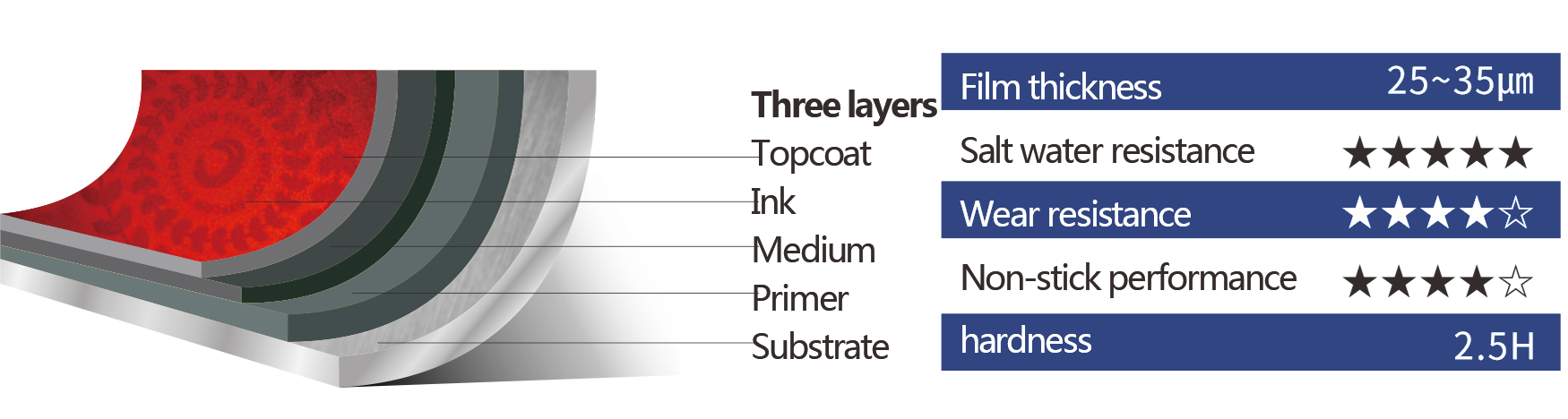

| Spraying method | 4 layers (primer, middle paint, ink, top paint) |

| Primer sintering temperature and film thickness | 220~230℃ X 20 minutes / 10~15㎛ |

| Sintering temperature and film thickness of middle paint | 400~420℃ X 20 minutes / 10~15㎛ |

| Ink sintering temperature | 400~420℃ X 20 minutes |

| Topcoat sintering temperature and film thickness | 400~420℃ X 20 minutes / 5~10㎛ |

| Not sticky | 30 times |

| Abrasion test | 46000 times |

| Salt water resistance test | 120 hours |

| Adhesion test | Normal |

| Discoloration test | Normal |

浙公网安备33020602000690号