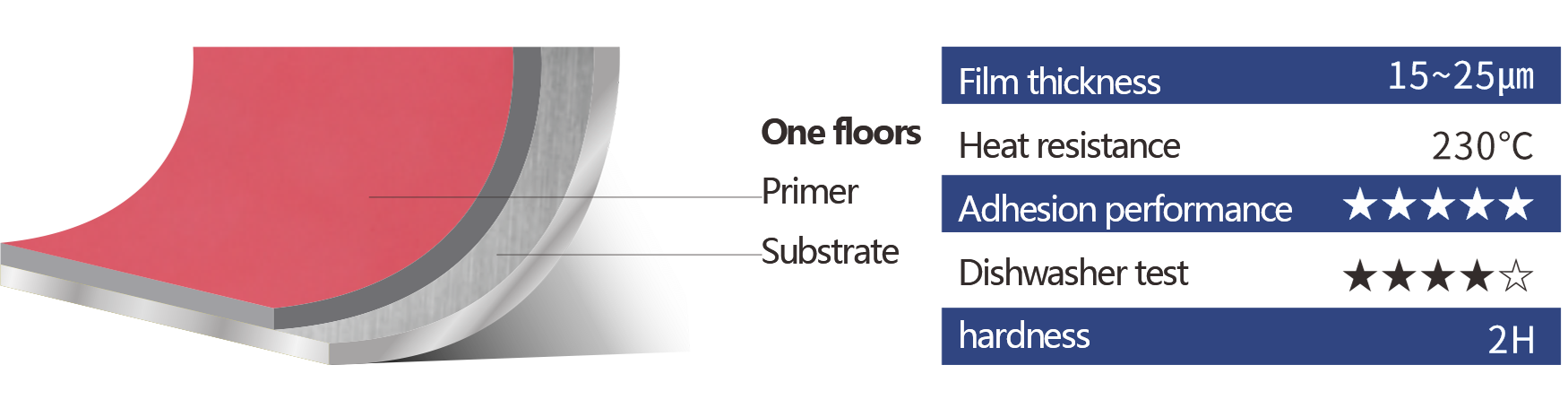

This product is made of silicone modifiedpolyester resin, heatresistanceabove.

230℃andcanbeproducedavarietyofcolors.

Itismainlyusedascookwareexternal coatingsuchasfryingpans,andsomeofthem.

aresuitablefor industrial supplies accordingtotheiruses.

It is generally suitable for aluminum alloy with fast heat

transfer in kitchen utensils.

Darong cooperates with a well-known international testing institution(SGS), to ensure that products and services comply with global standards and local regulations, and we can tell you or your end clients. It is proved that the High-Temperature Heat Resistance Solvent-BaseCoating coatings are in line with domestic and international standards and specifications.

| Test items | Test method | Test results |

| Pencil hardness | Use a MITSU-BISHI HB~9H pencil, with an inclination of 45°, with a force of about 1kg to test whether the film is peeled. | 2H~3H tested according to ASTM-7875 test method |

| Impact resistance | Use a ball with a diameter of 0.5 inches and a weight of 1.5 kg and throw it down from a height of 50 cm to check if the coating film is peeled off. | No exception |

| Solvent resistance | Dip the cloth with MEK solvent or thinner, and rub the film back and forth to observe whether the film peels off. | 15 times or more |

| Adhesion | Use a knife to mark 100 square grids with 2 mm intervals, and use tape to completely glue and tear apart. Repeat 10 times. | 100/100 No exception |

| Alkali resistance | Add 5% NaCO3 and leave for 48 hours. | No exception |

| Boiling resistance | Put it in boiling water for 1 hour. | No exception |

| High temperature resistance | Keep it at 250 degrees for an hour and then put it in water to cool down rapidly. | No exception |

浙公网安备33020602000690号